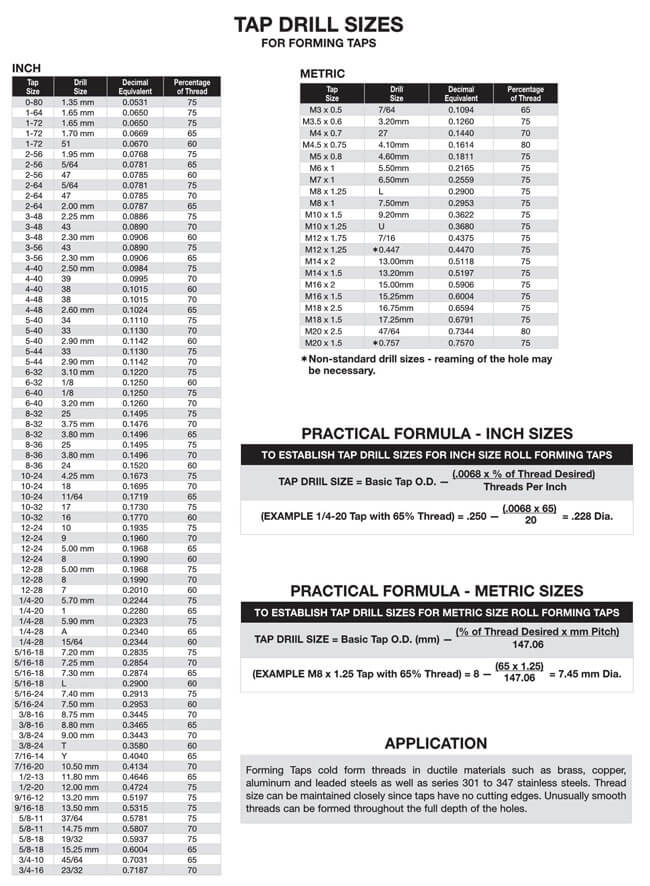

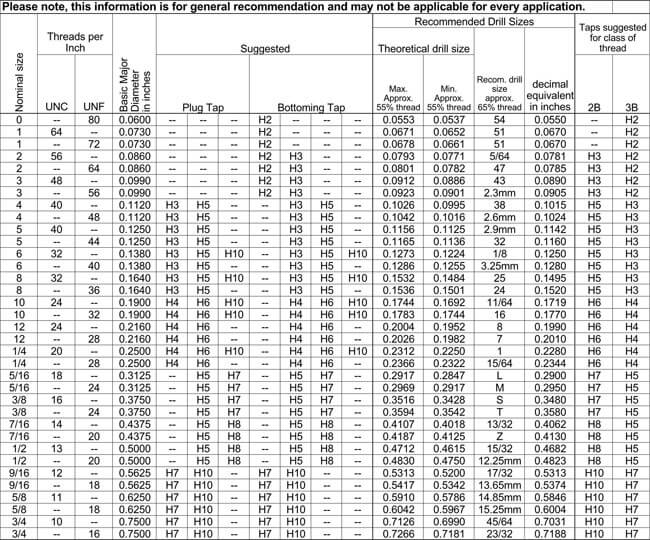

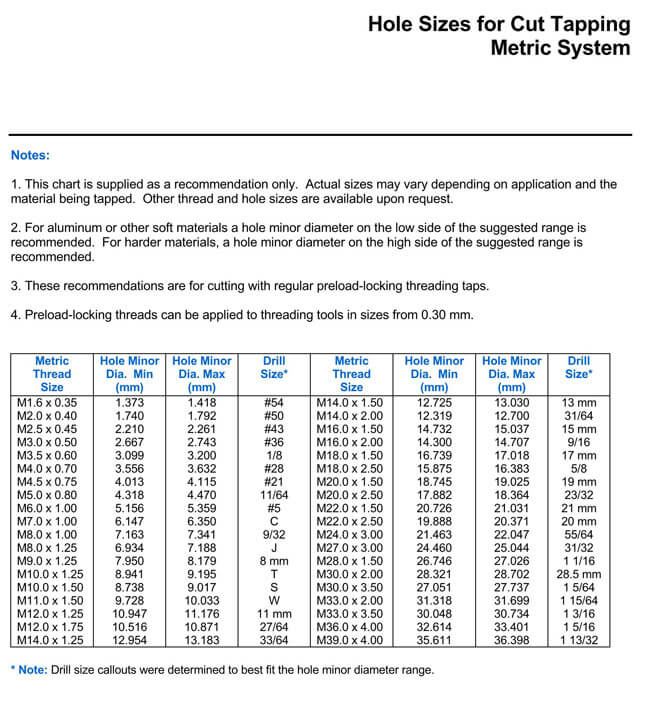

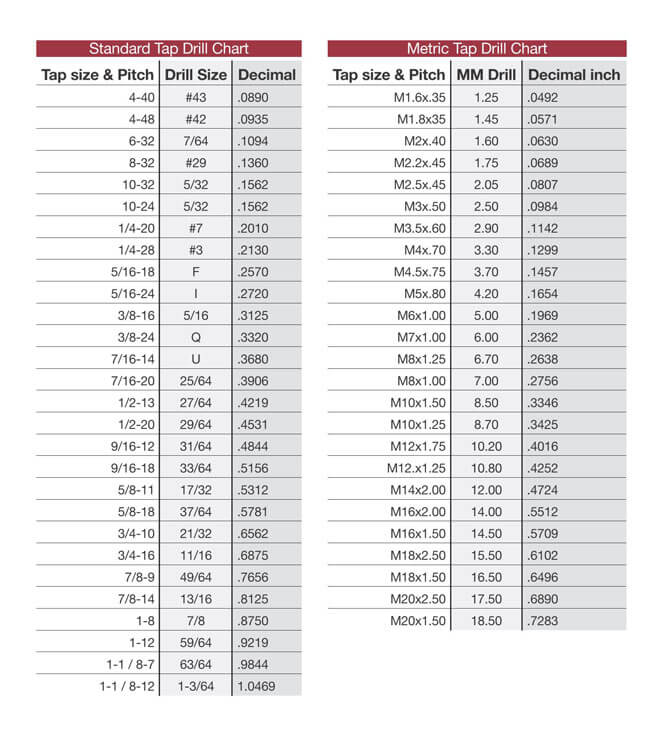

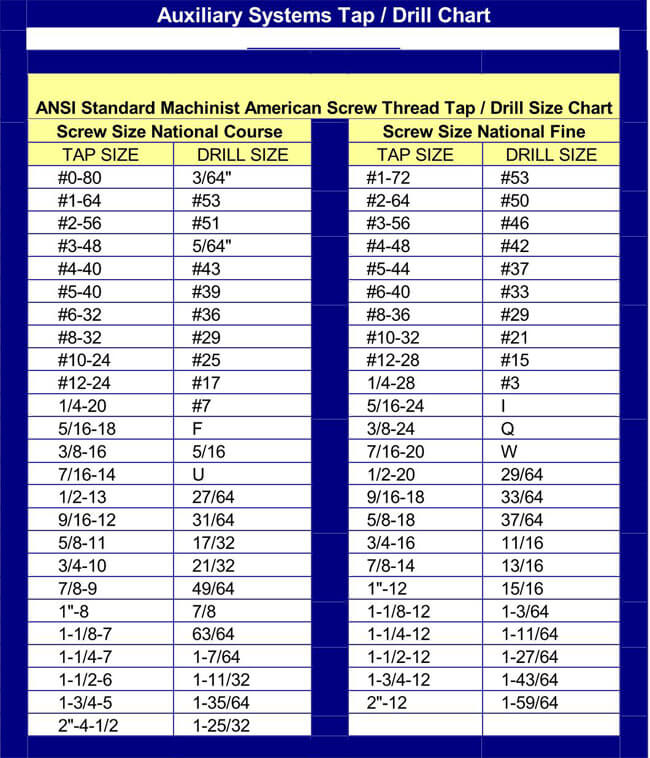

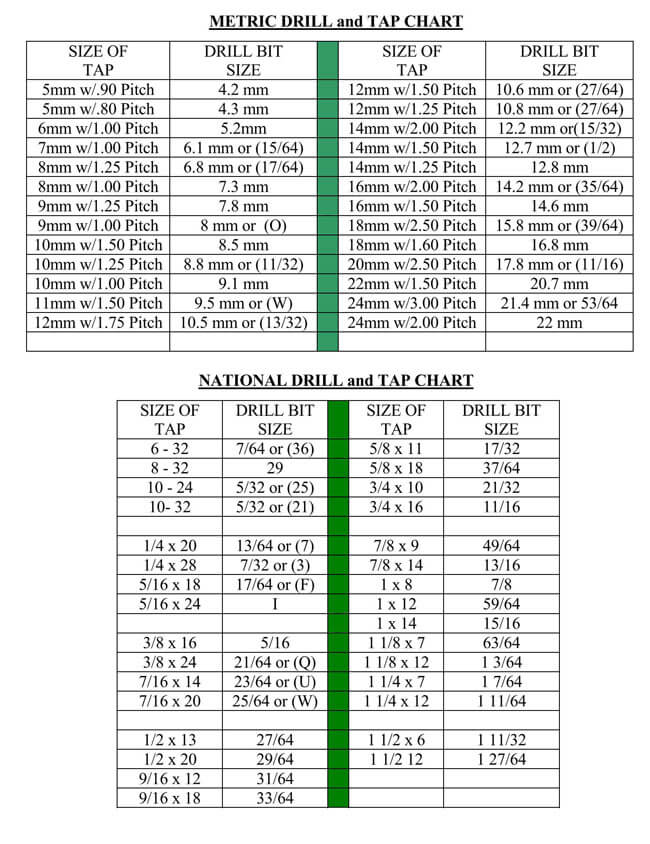

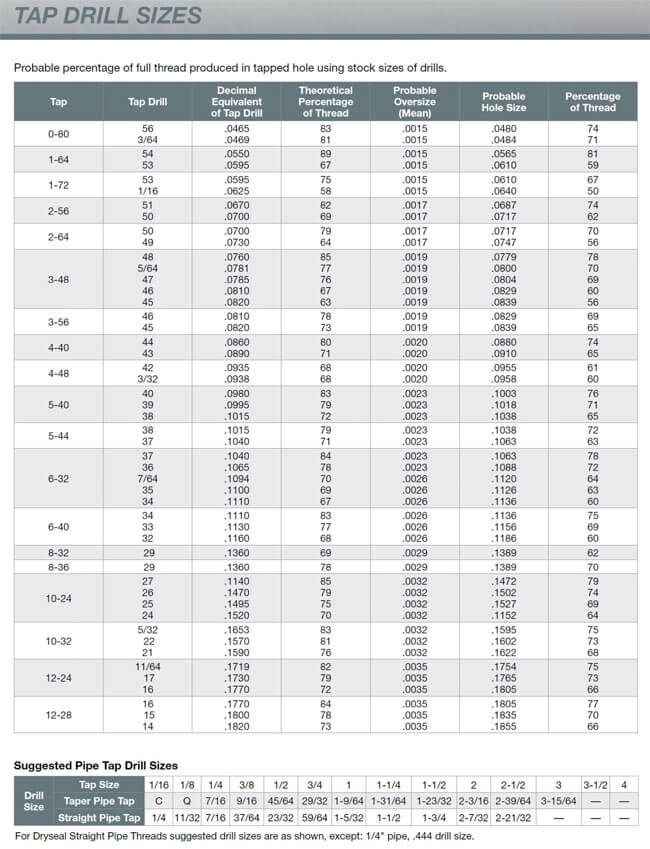

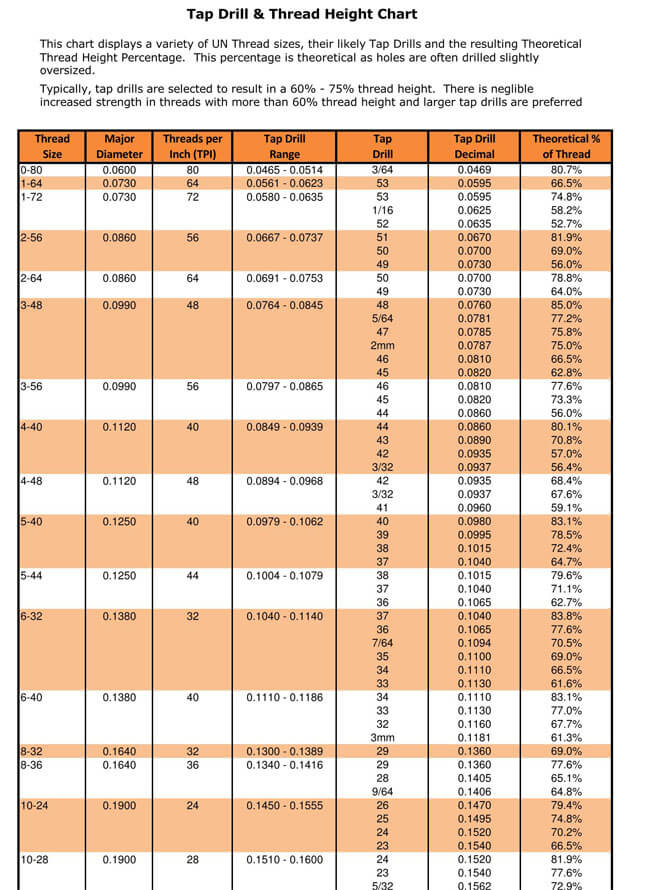

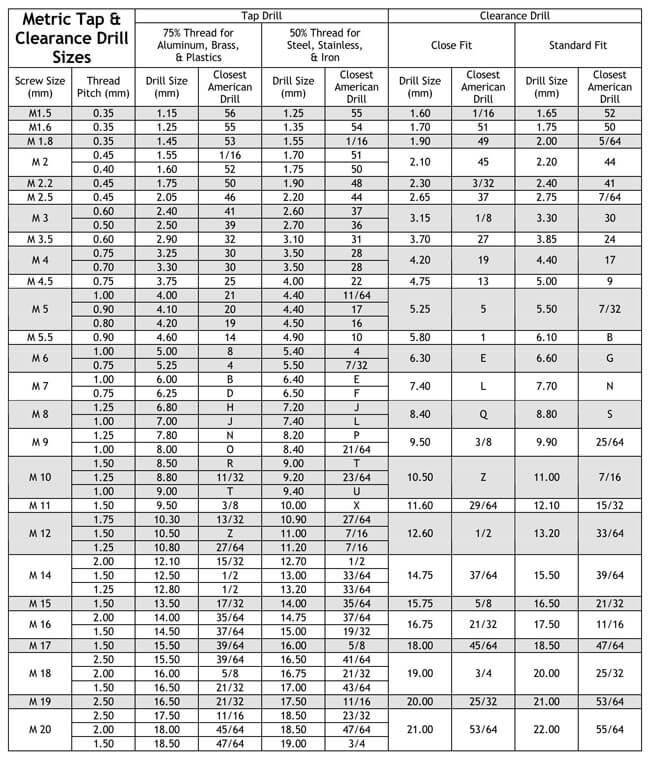

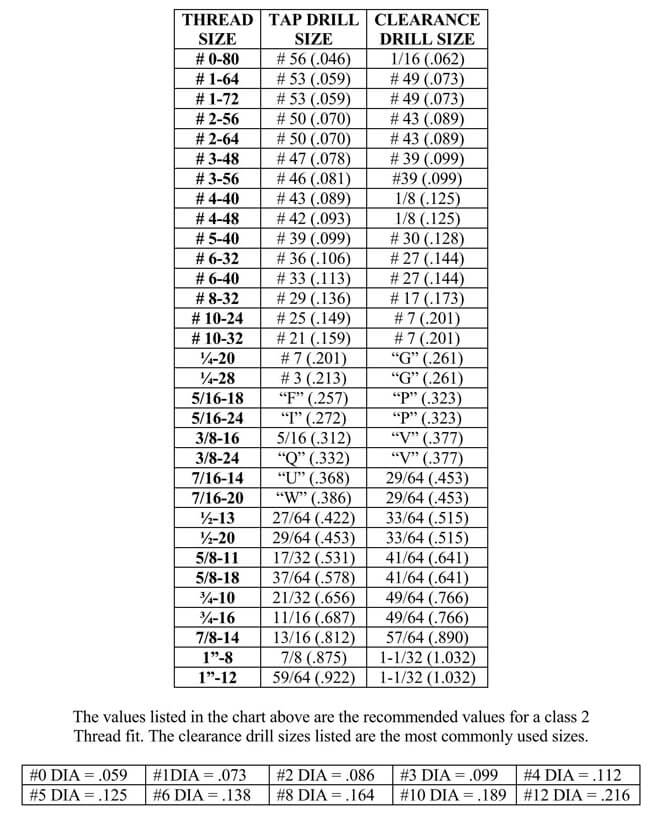

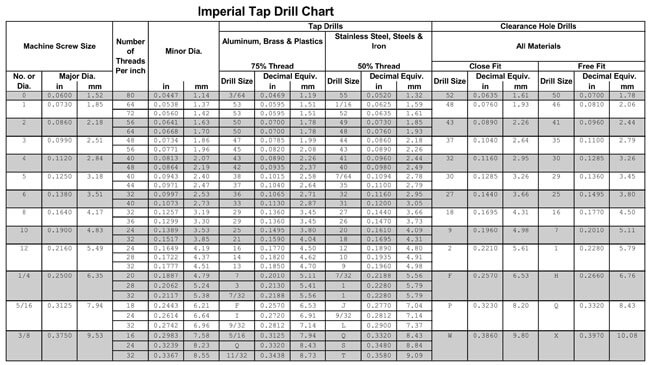

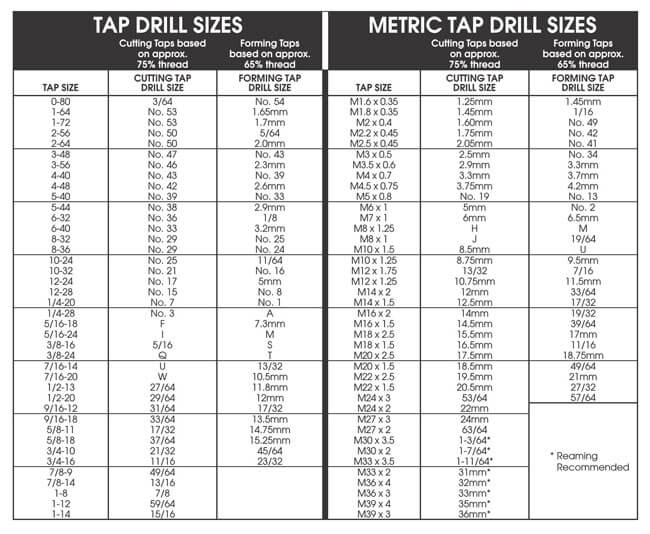

A drill tap size chart is a diagram from which the right sizes of the drill bit are obtained when creating an opening. Usually, the tap drill charts help manufacturers come up with a tightly matching pair of male and female threads.

Tap and die overview

Every mechanist will tell you the significance of having a tap and die in the manufacturing industry. They work hand in hand to create screws, nuts and fasteners necessary for construction. Before we go deep into these items, let’s first know what they mean.

A tap is a screw-like device used to create female screw threads.

In other words, they are tools that are used to cut threads into a hole so that the holes can receive fasteners or bolts more effectively. In many cases, these devices are made of carbon steel to make them strong for the job.

A die, on the other hand, is a special tool used to cut the male portion of a mating pair of the metal fastener through a process known as threading.

In other words, it’s a device used to cut threads on a bolt (male screw).

Download Free Templates

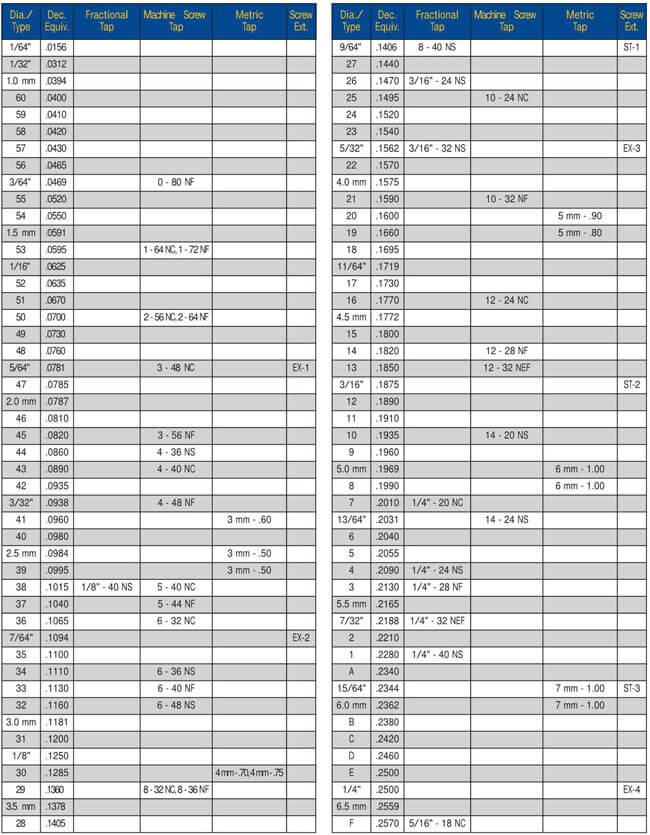

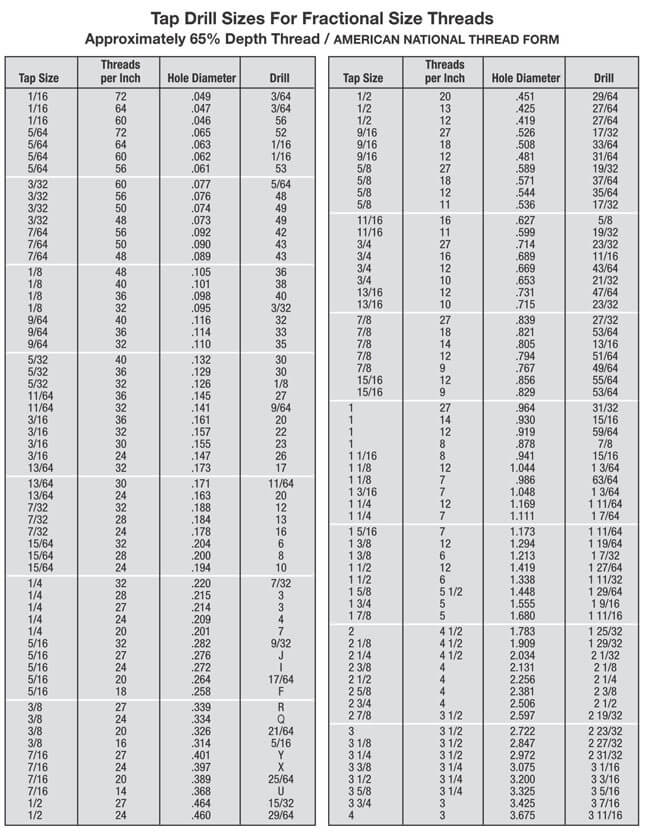

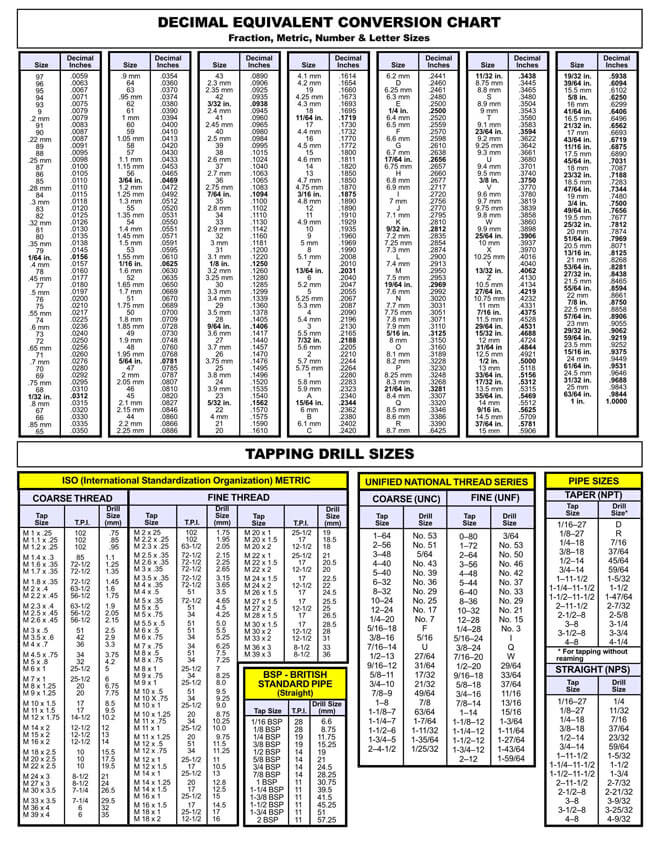

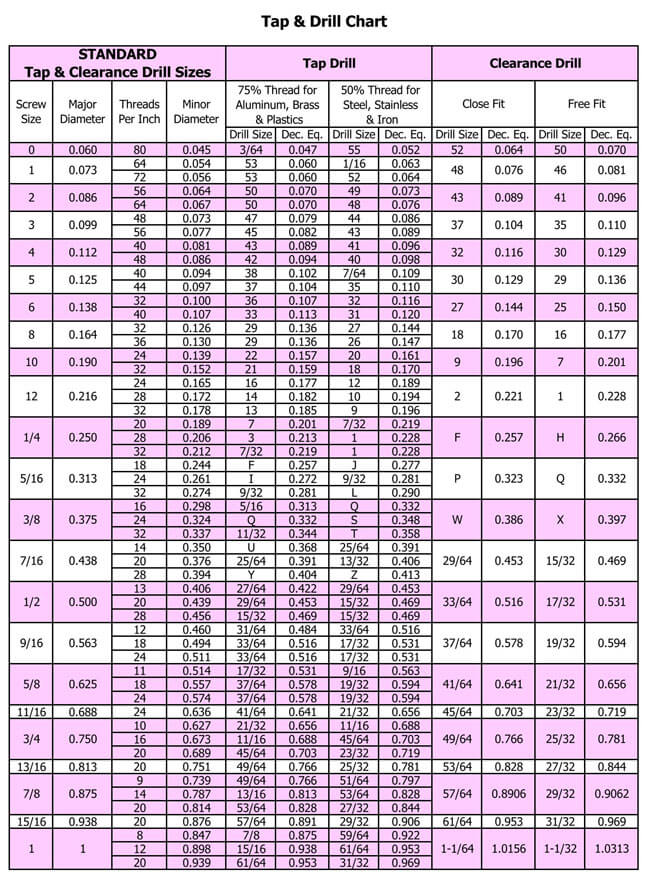

Converting Drill Bit Sizes

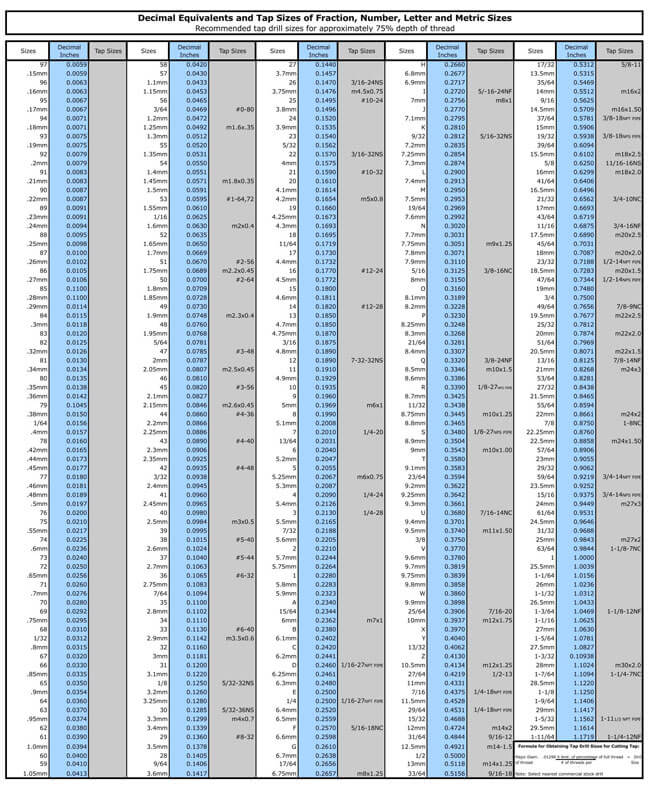

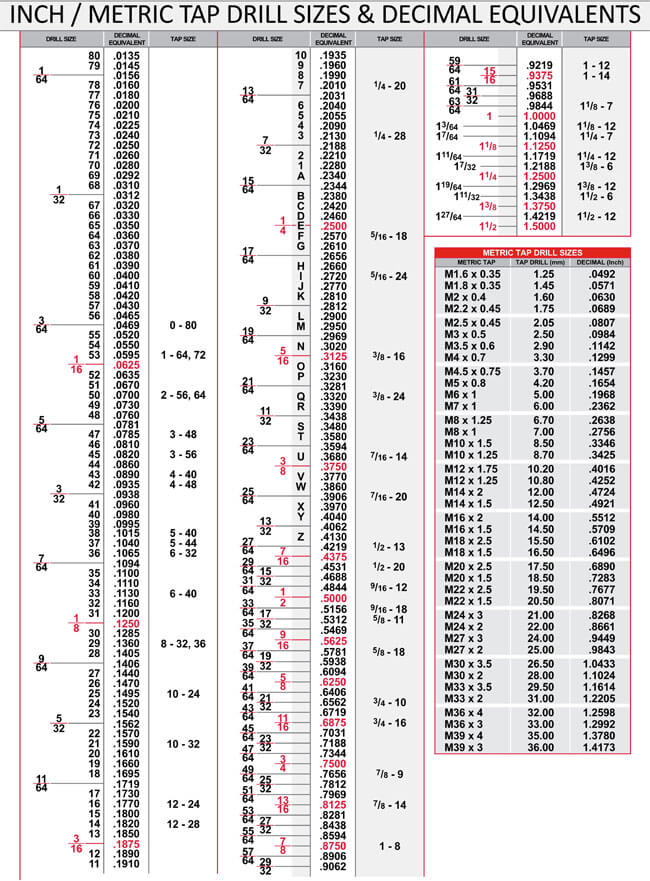

First, you need to check the tap drill chat to confirm the corresponding drill bit size. These charts are easily accessible on internet. When you get the right tap chart, you will need taps for the manufacturing parts. A hole and thread will be made on the material to form a female screw. Since there are various ways of making holes, the most recommended one is using a tap.

Standard taps do have one drill bit size or more. The bit size(s) are often bigger than the thinnest area of the male screw. If you are looking for right-sized drill and tap size, you will have to know whether the screw you need is coarse or fine. With such information, you can easily determine the correct drill bit size. Additionally, the taps can also make varied hole depths between 50 to 100 percent about the size of the hole.

Usage of Tap Drill Chart

Generally, it is impossible for you to know the size of the tap drill to use for your screw or bolds without a good tap drill chart.

A tap drill chart will help you in the following manner:

Determine the size

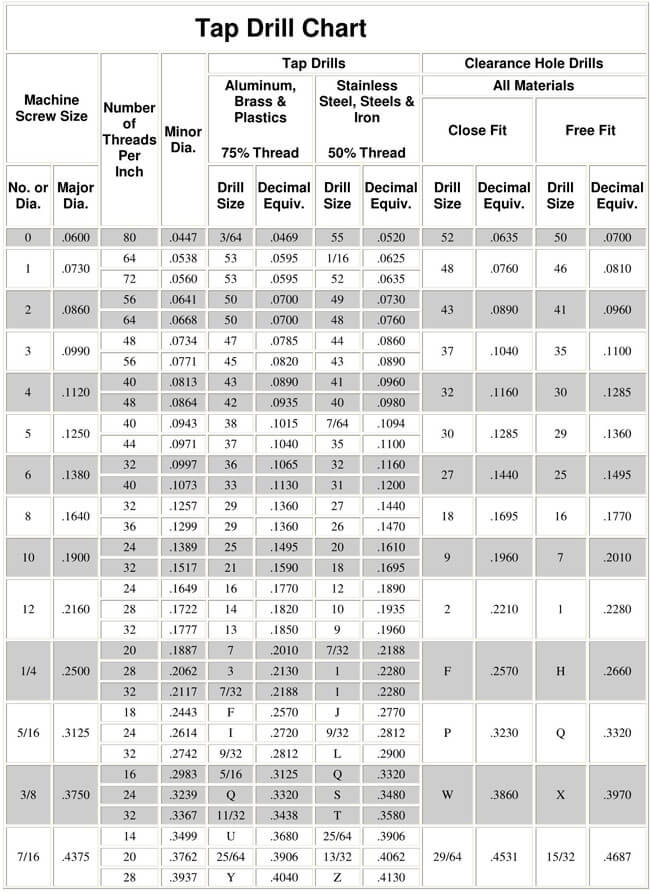

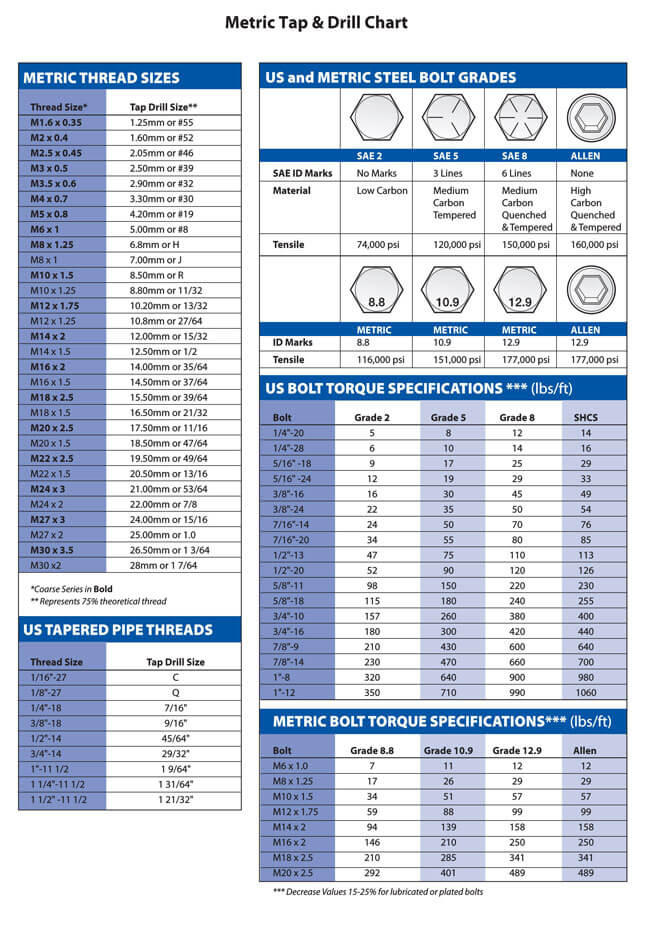

Because the types of tap and drills vary in size and materials, the charts will help you come up with an appropriate size that suits your drilling project.

Compare diameter in inches

Tap drill charts help machinists compare the size of a drill bit so as to come up with the right type that would create the right size of the hole. Once the correct drill bit is determined, the mechanists then proceed with drilling the hole up to the recommended length. Taps are then placed to make guides of the right size. Note that it is the correct usage of taps and charts is that leads to correct guides.

The following is an illustration of how best you can use these charts to make your guides:

- First, you need to create a hole inside the material.

- Using your tap and charts to confirm the correct size, re-drill the hole while creating threads inside.

- Put the square of the tap above the holder and tighten.

- Place the tip of the tap into the hole in a perpendicular direction and gently press inside.

- Let the tap cut threads in the wall of the hole until you reach two turns.

- Turn the tap backward, preferably 3 to four turns. This will help loosen the chip.

note

Note that the dies also follow the same protocol. However, with the die, you will use a round rod instead of a drilled hole. Also, you need to pick a die of the same size as the rod to make it work effectively.

EXAMPLE

if your rod is 3/4 inches, then the die should equally be ¾ inches.

Understanding the Chart

More often, you will find that the tap and die chart have a similar correspondence with a specific drill size and diameter. As a mechanist, you only need to read the chart to get a corresponding match. The match should contain the right drilling characteristics, such as thread count.

Apart from that, for understanding the chart one must know the types of the tap. Generally, there are various types of taps you will find in the market.

Depending on your use, here are some of the most common:

- Taper taps: These are the most common types of taps. Usually, their first 8 to 10 threads are often tapered to make thread cutting easy and efficient.

- Bottom tap: These taps have no tapers unless for the last 1 to 1.5 threads. The reason for this is to make the thread all the way to their bottom reach.

- Plug taps: These taps work on threads that are submerged halfway into the hole.

- Machine screw taps: These taps are designed to create threads in holes with a small diameter. This makes them the smallest on the list.

- Straight flute taps: These taps are designed with a ribbed or corrugated surface for efficient cutting. Usually, they are the simplest and affordable in the market. Also, they can be used manually by use of hands.

Now, by reading the chart, one can find the perfect size of the hole to drill.

Final Words

Taps and dies are very important devices in the manufacturing industry. They help create fasteners, screws, and bolts that are necessary for our day-to-day construction. If you inspire to be a professional mechanist, it is recommended that you know their operations and mechanisms.